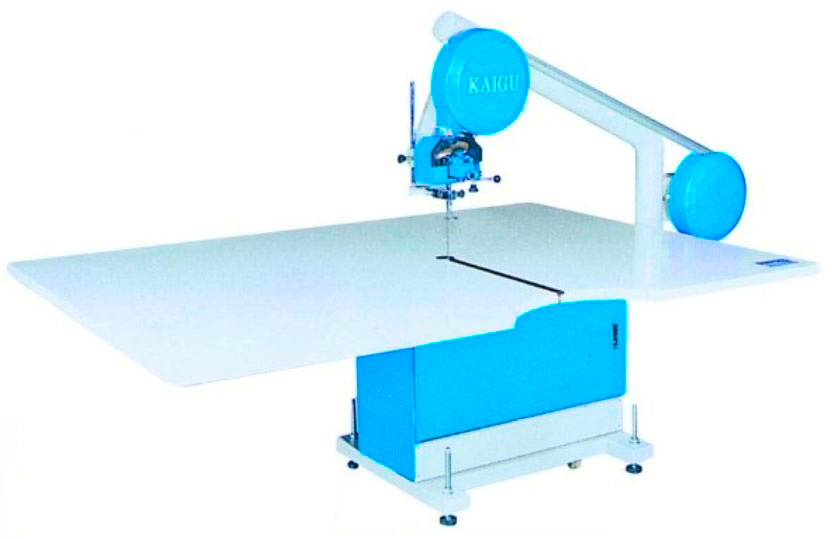

Different model available

BK-with air cushion & speed adjustment

BKM-without air cushion with speed adjustment

Special Technology Band Knife Cutting Machine with special silicon

gliders , 70% more safety features , auto adjustment , less

maintenance

Successfully Running in Garmenting Industry , Filter Industry etc.

BK-with air cushion & speed adjustment

BKM-without air cushion with speed adjustment

QP-1 chopping device is special equipment that is used for cutting piping trim in the field of garments. It is mainly used in series of BC/DC Band Knife Cutting Machine to cut the knitted fabric of wound roll (internal non-paper-core or using special core to coil with) transversely. Thus, It forms piping trim. QP-1 chopping device can be installed in series of BC/DC band knife cutting machine through guiding, simply and conveniently and does not need to change the measure. This device has a locator, which can cut piping trim width that you need. And it is accurate to millimeter

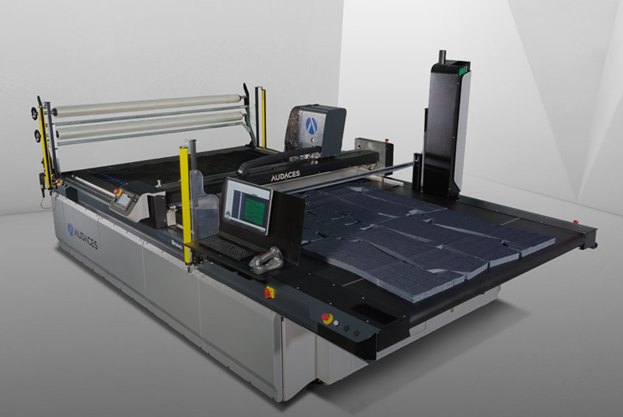

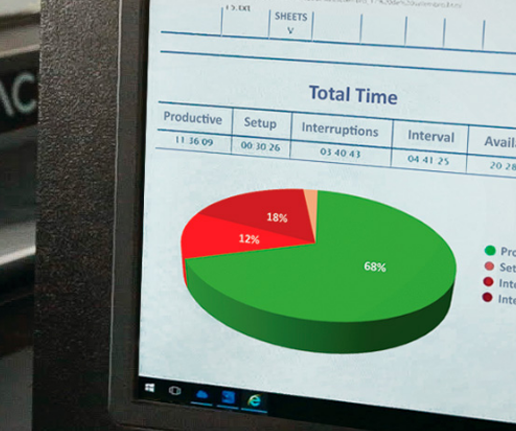

Audaces Neocut Bravo is a machine for the Industry 4.0. With short deadlines, new product requirements and an increasingly competitive landscape, companies need to adapt and respond to change quickly. Holding information to create efficient planning is critical to getting the best results. With Neocut Bravo, the time, day, week and month of production are timed, aligned with your company goals and automatically provided for you to make decisions in complete safety. The continuous monitoring of the working conditions allows remote maintenance, remote diagnosis and the quick resolution of any situation. Manage better with the intelligence of Neocut Bravo integrated with the Neocut Mobile application to prevent losses and speed up your production. Keep up to date in real time to produce more.

A GLOBAL PROJECT. THE ONLY ONE MANUFACTURED IN BRAZIL AND ITALY.

SEE THE 6 GREAT ADVANTAGES FOR THOSE WHO USE AUDACES NEOCUT BRAVO:

The innovations developed by Audaces are already anticipating the

future of the industry 4.0 in fashion, where all process management

can be done with accurate, integrated data provided by intelligent

equipment in real time and with remote access. This means that your

production may literally be in the palm of your hand. On your

smartphone, for example. It's the Internet of Things (IoT) coming

into your industry. With short lead times, new product demands and

an increasingly competitive market, the fashion industry needs to

adapt and respond to those changes quickly. When we speak of

automatic cutting, delivery on time, of perfectly cut pieces, we

speak of Audaces Neocut Bravo.

INTEGRATION IS THE CONCEPT, EFFICIENCY IS THE GOAL AND PRODUCTIVITY

IS THE RESULT.

But all the innovation promoted by Audaces, comes not simply from

the

application of new technologies. It is the result of the practical

accompaniment of the day-to-day production of our customers,

listening

to the suggestions of those who work intensely to improve processes

and

results. Audaces is present throughout the production cycle, from

creation to execution, so it is able to relate information and

perfect

systems. Each automation project is unique, but it takes advantage

of

all the experience and knowledge already acquired. The support we

give

you does not end in the acquisition. You become a partner with

Audaces,

the technology owner, and you can keep your equipment up-to-date.

Count

on our experts to make the right decision and to achieve and exceed

your

goals. Our focus is the sustainability of your business.

A GLOBAL PROJECT. THE ONLY ONE MANUFACTURED IN BRAZIL AND ITALY.

SEE THE 6 GREAT ADVANTAGES FOR THOSE WHO USE AUDACES NEOCUT BRAVO:

The innovations developed by Audaces are already anticipating the

future of the industry 4.0 in fashion, where all process management

can be done with accurate, integrated data provided by intelligent

equipment in real time and with remote access. This means that your

production may literally be in the palm of your hand. On your

smartphone, for example. It's the Internet of Things (IoT) coming

into your industry. With short lead times, new product demands and

an increasingly competitive market, the fashion industry needs to

adapt and respond to those changes quickly. When we speak of

automatic cutting, delivery on time, of perfectly cut pieces, we

speak of Audaces Neocut Bravo.

INTEGRATION IS THE CONCEPT, EFFICIENCY IS THE GOAL AND PRODUCTIVITY

IS THE RESULT.

But all the innovation promoted by Audaces, comes not simply from

the

application of new technologies. It is the result of the practical

accompaniment of the day-to-day production of our customers,

listening to the suggestions of those who work intensely to improve

processes and results. Audaces is present throughout the production

cycle, from creation to execution, so it is able to relate

information and perfect systems. Each automation project is unique,

but it takes advantage of all the experience and knowledge already

acquired. The support we give you does not end in the acquisition.

You become a partner with Audaces, the technology owner, and you can

keep your equipment up-to-date. Count on our experts to make the

right decision and to achieve and exceed your goals. Our focus is

the sustainability of your business.

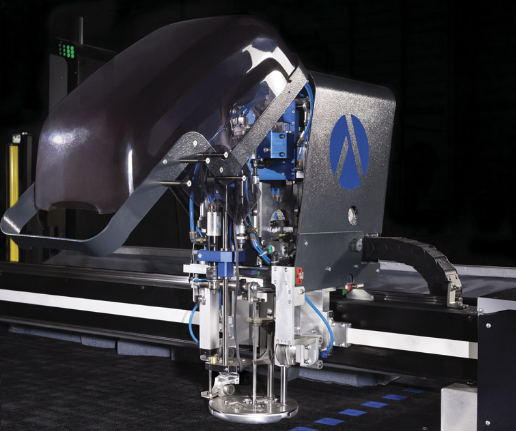

More than 300 sensors ensure that Neocut Bravo adopts the best cutting condition for different types of materials and different layer heights. With them, the productivity in the exquisite execution of the projects is assured, without losses, in scale and with finish.

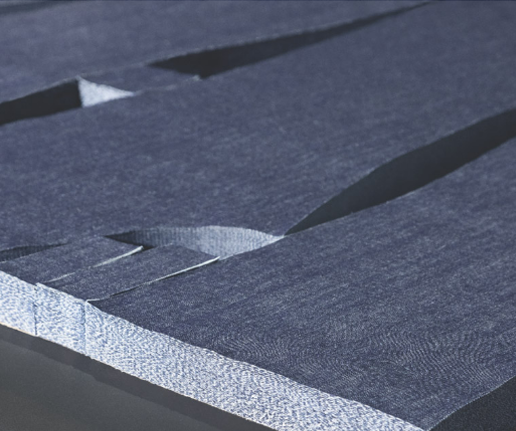

Cutting with zero spacing between the patterns, the machine sets the starting points automatically, guaranteeing cutting quality from the first to the last layer, with maximum use of raw material.

The Intelligent Blade system and sensors enable Neocut Bravo to accurately cut dense or light materials. The bending of the cutting blade is monitored continuously to ensure the perfect cut, regardless of the complexity of the patterns or the characteristics of the fabric. Contours, markings and noths are made with precision.

Neocut Bravo is the safest cutting machine in the world. It interrupts its operation as soon as the machine's work area is invaded. The return to the operation is automatic and instant, at the point that it stopped at, without the intervention of the operator.

Easy to use and easy to learn, Neocut Bravo has an interface that makes it easy to learn all of its features.

With commercial electronics and first-line parts, Neocut Bravo guarantees low maintenance costs and energy savings.

KAIGU has been serving the Indian Market from last 30 Years in,

Garment Export, Home Furnishing, Leather Finishing Industry, High

Fashion, Shirt Manufacturing etc. and is well-known brand in the

world of clothing machinery.

Its products include series of: -

For Cutting machines, Different models available for Garment Export,

Home Furnishing, Leather Finishing Industry, High Fashion, Shirt

Manufacturing etc.

Straight knife cutting machines are used to cut various sized

components. This is the most commonly used piece of equipment for

cutting bulk garments. It moves along the cut contours while the

fabric spread remains stationary. The machines are manoeuvrable and

can cut in a curvilinear pattern. The straight-knife cutting machine

is the most popular and versatile in the world. Available in all

standard electrical configurations, with the industry's widest range

of sizes and blade speeds. It is the most useful cutting tool in

garment cutting. This knife is used in over 99 percent of cases in

the apparel industry.

Because the cutter on this machine is straight, it is known as a

straight knife cutting machine. It is used on woven and knit

fabrics. Depending on the cutting item, numerous types of straight

knives are utilised in this equipment. This equipment is very

efficient. A cut spread's maximum height is 300 mm. The machines

range in weight from 5 to 20 kg. Heavier machines are more difficult

to manoeuvre. Only straight-knife machines may be used in

small-capacity production units.

The main parts of this machine are straight knife, electric motor,

handle, grinder, base plate, stand/ knife holder, lubricating unit,

wheel etc.

Could be used to cut higher depth of fabric.

Knife height is 10 cm to 33 cm.

Knife stroke is 2.5 cm to 4.5 cm.

Motor r.p.m. is 3000 to 4000.

Auto Sharpening Tool for better and precise cutting experience in

KAIGU needle Detector Machine

Auto lubricating unit works for this machine.

Different types of knife edge are used for cutting different

objects. Such as, straight edge, wave edge, sew edge and serrated

edge.

A Handle for the cutter to direct the Knife.

Knife guard is attached to the front of the knife.

Sharp and heavy corners can be cut.

Maximum 70% of knife height is used for fabric lay.

Wheels are under the base plate to move the machine smoothly.

Knife cut the fabric very fast due to high speed of motor. Suitable

for mass trimming cotton, woolen, linen leather and chemical fiber

goods, etc.

Neat cutting, small-curvature radius curvilinear cutting.

Low noise, stable running, easy to operate and high efficiency.

Incorporated with an auto knife-grinding device, easier to

operate.

| Model Power | Max.Thx. of cutting | Power |

|---|---|---|

| ZCD-110M | 110mm | 550w |

| ZCD-160M | 160mm | 550w |

| ZCD-210M | 210mm | 550w |

| ZCD-260MH | 260mm | 750w |

| ZCW60-M | 60mm | 220w |

| ZCW85-M | 85mm | 220w |

| ZCW110-W | 110mm | 220w |

| Electricity | 220V 1PH 50Hz. |

| Model | Max.Drilling Depth | Range of Temp. | Power Output |

|---|---|---|---|

| ZK-2 | 150mm | 0-200oC | 100W |

| ZK-110-3 | 110mm | 0-200oC | 350W |

| ZK-160-3 | 160mm | 0-200oC | 350W |

| ZK-210-3 | 210mm | 0-200oC | 350W |

| Electricity | 220 1Ph 50Hz |

| Model Power | Max.Thx. of cutting | Power |

|---|---|---|

| YC20-MII | 20mm | 80w |

| YC23-MII | 23mm | 80w |

| YC25-MII | 25mm | 100w |

| Electricity | 220V 1PH 50Hz. |

Knife sharpening device ensure the knife being sharp. The pressing device can press the fabric and avoid it stagger when it is being spread. it has the function of pharrenings so the blade is always keep sharp. It has the function of pressing, which can help press tight the fabric that have already been spread. In this way, misplacement can be avoided. It has the function of automatic cutting. Press the button and it begins to cut the cloth automatically rapidly and accurately. It has the function of recording the layers of the fabric that have already been spread automatically. It has the function of setting the width. It can set the distance within which the cutter moves according to the width of the fabric.