Flatbed Fusing Machine

1. AG-964 Multipurpose Machine

Universal Flat Bed Fusing Machine (Multi-Purpose with suction system.) with digital timer and temperature controller Aluminum Body, Specially designed for High Fashion Garments and Uneven Fabric / Stone Works / Swarovski. Used mostly by High Fashion Designers. Less Power Consumption due to the Block Heaters Technology.

A very light fusing machine designed in almost 100% Aluminum body, special type of aluminum upper buck is made so that it can maintain heat & more pressure which helps in fine fusing, special bed & cushion are given on the lower buck which helps in given the best result of fusing, with table stand with temperature controller and suction of lower buck for instance cooling.

Features

- Designed specifically for fusing.

- Convenient to use with perfect fusing, as available a wide working range.

- Automatic belt control with right and left.

- Micro sensors at the end of the roller.

- Roll-rewinding function optional.

- Fully automatic belt deviation.

| Model | AG-964 Premium | AG-964 Ultra Premium |

|---|---|---|

| Temp Range | 0-300 C | 0-300 C |

| Power | 2.1 KW / Hr | 2.5 KW / Hr |

| Working Table ( in mm) | 1200x480 | 1200x480 |

| Voltage | 220 V, 1Ph | 220 V, 1Ph |

| Dimension HxWxL ( in mm) | 1200x705x1370 | 1200x705x1470 |

2. 964 Premium

Universal Flat Bed Fusing Machine (Multi-Purpose with suction system.) with digital timer and temperature controller Aluminum Body, Specially designed for High Fashion Garments and Uneven Fabric / Stone Works / Swarovski. Used mostly by High Fashion Designers. Less Power Consumption due to the Block Heaters Technology. A very light fusing machine designed in almost 100% Aluminum body, special type of aluminum upper buck is made so that it can maintain heat & more pressure which helps in fine fusing, special bed & cushion are given on the lower buck which helps in given the best result of fusing, with table stand with temperature controller and suction of lower buck for instance cooling.

Features

- Designed specifically for fusing.

- Convenient to use with perfect fusing, as available a wide working range.

- Automatic belt control with right and left.

- Micro sensors at the end of the roller.

- Roll-rewinding function optional.

- Fully automatic belt deviation.

| Model | AG-964 Premium | AG-964 Ultra Premium |

|---|---|---|

| Temp Range | 0-300 C | 0-300 C |

| Power | 2.1 KW / Hr | 2.5 KW / Hr |

| Working Table ( in mm) | 1200x480 | 1200x480 |

| Voltage | 220 V, 1Ph | 220 V, 1Ph |

| Dimension HxWxL ( in mm) | 1200x705x1370 | 1200x705x1470 |

3. PY1 & BL1

PY & BL Fully Automatic Air Driven Heat Transfer Press

PY & BL Series fully automatic air driven heat transfer press is a kind of heating pressing machine. This machine is mainly used for making pockets of non-thread swing process, for the fusing of clothing pieces and for one point printing of clothes, hats, shoes, socks and stocking. With this machine, not only can normal printing be done, but also the transferring of flock printing and rubber printing.

Features

- Fully automatic compress air driven type.

- The horizontal pressure system gives uniform, assuring no slippage of product.

- Pressure pressing time and temperature control can be made easily.

- The Teflon sheet is used on the upper aluminium press plate doesn’t soil and it can be cleaned easily.

- The silicon mat is used one the lower aluminium press plate.

4. Flatbed Fusing Machine

An innovation in flat bed fusing machine almost 100% aluminum parts with suction fully automatic multipurpose fusing machine for even an uneven garments seroski transfer, paper leather transfer specially design for designers high fashion garment and leather garment.

Features

- A very light fusing machine designed in almost 100% Aluminium body.

- Special type of aluminium upper buck is made so that it can maintain heat & more pressure which helps in fine fusing.

- Special bed & cushion are given on the lower buck which helps in given the best result of fusing, with table stand with temperature controller and suction of lower buck for instance cooling.

| Model | Work table size | Power Kw/h | Temperature | Time Delay |

|---|---|---|---|---|

| AG-35 | 15”x15” | 1 | 50-200 C | 1-60 S |

| AG-45 | 25”x16” | 1.5 | 50-200 C | 1-60 S |

| AG-55 | 33”x16” | 1.75 | 50-200 C | 1-60 S |

| AG-65 | 31”x25” | 2 | 50-200 C | 1-60 S |

| AG-75 | 40”x20” | 2 | 50-200 C | 1-60 S |

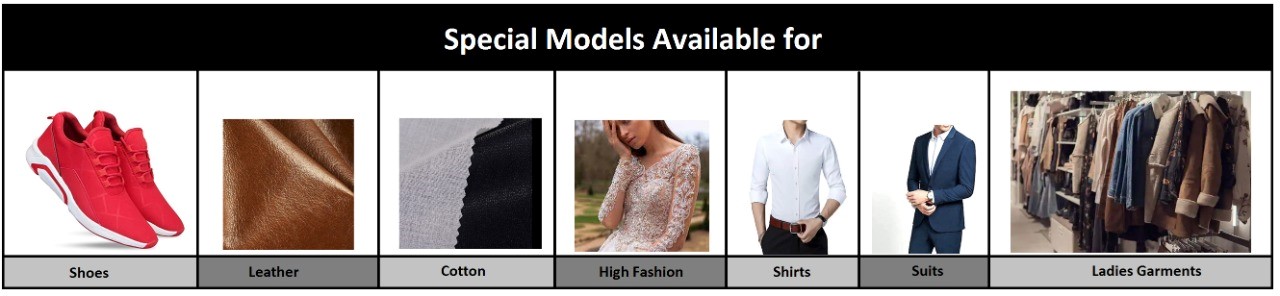

Our Products

- Audaces Apparel Cad CAM

- Garment Cutting Printing Plotters

- Fabric Inspection Machine

- Conveyor Type Fusing Machines

- Flatbed Fusing machine

- Cutting Machines

- Auto Cleaning Machine- Spot Removing Machines

- Thread Sucking Machine

- Needle Detector Machine

- Industrial Laundry Machines

- Calendering Machine - Flatwork Ironer Pressing Machine- Drying pressing Machine

- Dry Cleaning Machine

- All in one Fully Automatic Industrial Laundry Machine

- Electric and Oil Fired Boilers

- Vacuum Ironing Tables - Industrial Pressing Table

- Laundry Pressing Machine - Hot Plates

- Turn Key Laundry Projects

- Shirt & Trousers Pressing Machines- Automatic

- Jacket Blazers Suits Coats Forming Finishing Pressing Machine

- Shirt Making Machines

- Shoe Washing Machines

- Industrial Carpet Washing Machines

- Sewing Machines

- Industrial Washing Chemical - Solvents

Our Clients