1. AG-FASP-1011 & 1012

Features

- Aluminium buck is suitable for garment (customizable).

- Automatic LED

- Controller (8Programs) (Set : Close, Press, Steam, Vacuum).

- Period of step: 0.5/1.0/1.5/2.0/2.5 second.

- 3 level safety protection device.

- Output single on electric board (easy to check faulty).

- Stainless steel board, Steam heating system.

- Top buck steam spray (steam chamber supply much volume).

- Bottom buck has vacuum.

- Famous Pneumatic parts.

- Dimension L*W*H : 900x1200x2350 mm

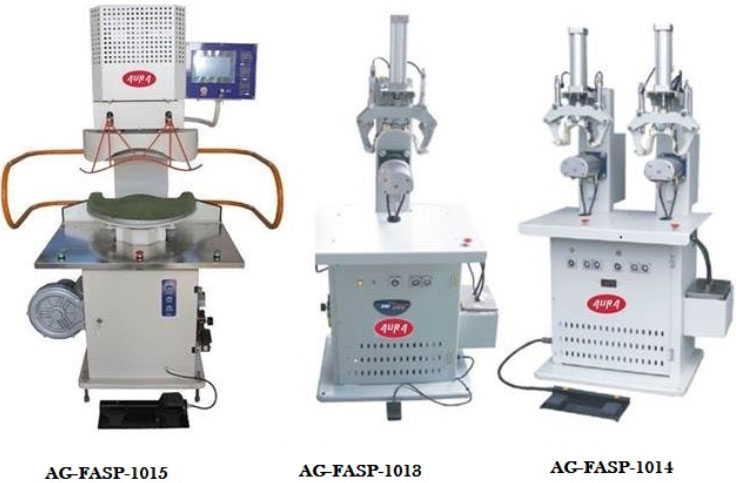

2. AG-FASP-1015, 1013 & 1014

Features

- Aluminium buck is suitable for garment (customizable).

- Automatic LED

- Controller (8Programs) (Set : Close, Press, Steam, Vacuum).

- Period of step: 0.5/1.0/1.5/2.0/2.5 second.

- 3 level safety protection device.

- Output single on electric board (easy to check faulty).

- Stainless steel board, Steam heating system.

- Top buck steam spray (steam chamber supply much volume).

- Bottom buck has vacuum.

- Famous Pneumatic parts.

- Dimension L*W*H : 900x1200x2350 mm

3. CUFF TURN AND PRESS MACHINE (PMM-SS-2C1)

Features

- Pressing the edges of the cuff helps the saving process.

- Able to fix and press the cuff.

- Automatic temperature control

4. AUTOMATIC POCKET CEREASER (PMM-PCS-PLC)

Features

- Special for folding of shirt sleeve vent.

- Able to fold a pair of sleeves vent with minimum colour difference.

- Control by micro-computer.

- Built in an automatic stacking device.

- Laser light is used for aligning the fabric.

- Different mould can fold different types of sleeve vent.

- Able to fold 3000-3600 pairs per shift.

5. SHIRT FRONT CREASING MACHINE (PMM-BFP-1)

Features

- Machine is design to fold shirt front.

- Laser light is used for aligning the fabric

- Average of 1900 folds per shift.

- Able to automatically stack up the material after finish.

- Option to install lining cutter for worker to put the lining tape inside the shirt front.

6. FORM FINISHER

Aura Body formers can fully meet the most discerning requirements for finishing jackets, coats and dresses in the laundry dry-cleaning and garments industries. Recently upgraded in both design and technical features, the AURA range of garment formers available in the following models.

- AG-94 with connection to external steam supplies and silenced operation utilizing steam operated valves.

- AG IB with a 20 Litters built in boiler and silenced operation using steam operated valves.

Features

- Both the machine are programmed by three timers: Steam, Hot air and cold air. The combination of three cycles, makes the garment press perfectly.

- The machines are constructed from stainless steel (INOX AISI 304); special powder coating on the body enables long rust fee life.

- The AG-94 IB with inbuilt boiler is an energy saving garment former. The steam condensate can return to the steam generator for lower steam consumption and does not require a steam trap.

- Available extras: Steam Iron assembly, Steam Gun, Water spray gun, alternative dummies which are interchangeable with the standard utility dummy which is supplied with the basic unit.

7. AURA ROTOR CABINET & REVOLVING FINISHING CABINET

Features

The ultimate solution in form finishing, the aura revolving finishing cabinet is a flexible system that can be used as a double form finisher, pants topper/jacket finisher or mini tunnel. The rotor cabinet system provides a high-production, deskilled operation for retail stores & distribution centers, hotels, uniform rental services, apparel manufacturers and drycleaners.

Our Clients