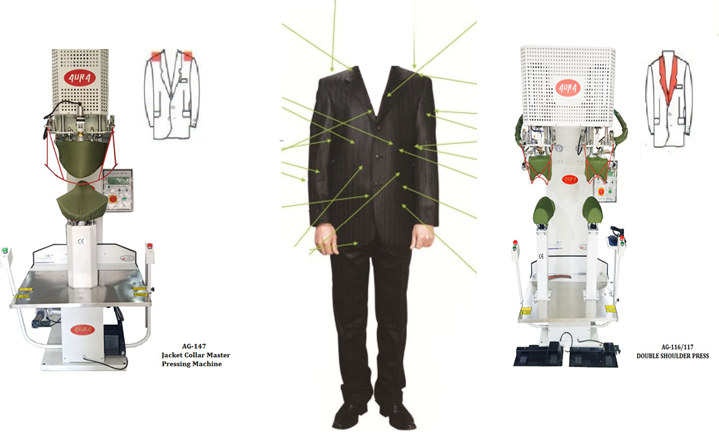

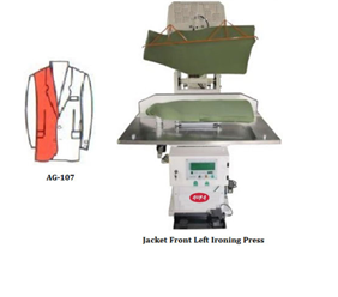

Jacket Pressing Machine

Jacket finishing machine

Features

- Automatic LED Controller(8 programs)(set :- Close,press,steam,Vacuum)

- Period of step:-.5/1.5/1.5/2.0/2.5 second

- 3 level safety production device.

- Output single on electric board (easy to check faulty).

- Stainless steel board, steam heating system.

- Top Buck steam sprays (italtmade value).

- Bottom buck vacuum.

- Famous Pneumatic parts

Features

- Pneumatic Pressure adjustment for every type of fabric

- Sensitive Ironing with Pat-pat Ironing function.

- Safety frame for operate safe optional

- Computer (PLG) Control

- Laser Pointer

Features

- Sclssors-type close & press.

- Metal buck is suitable for garment (Customizable)

- Automatic LED Controller (8 programs)

- Automatic LED Controller (8 programs)

- (Set: close, press steam, Vacuum)

- Period of step: 0.5/1.0/1.5/2.0/2.5 second

- 3 level safety protection device.

- Output signal on electric board (easy to check faulty)

- 180 mm length shock absorber (long life)

- Stainless still board, Steam heating system.

- Top buck steam spray (Italy-made Valve)

- Bottom buck has vacuum

- Famous Pneumatic parts.

Features

- Pneumatic Pressure adjustment for every type of fabric

- Sensitive Ironing with Pat-pat Ironing function.

- Safety frame for operate safe optional

- Computer (PLG) Control

- Laser Pointer

Features

- Sclssors-type close & press

- Metal buck is suitable for garment (Customizable)

- Automatic LED Controller (8 programs)

- (Set: close, press steam, Vacuum)

- Period of step: 0.5/1.0/1.5/2.0/2.5 second

- 3 level safety protection device.

- Output signal on electric board (easy to check faulty)

- 180 mm length shock absorber (long life)

- Stainless still board, Steam heating system.

- Top buck steam spray (Italy-made Valve)

- Bottom buck has vacuum

- Famous Pneumatic parts.

Features

- Automatic LED Controller(8 programs)(set : - Close,press,steam,Vacuum)

- Period of step:-.5/1.5/1.5/2.0/2.5 second

- 3 level safety production device.

- Output single on electric board (easy to check faulty).

- Stainless steel board, steam heating system.

- Top Buck steam sprays (italtmade value).

- Bottom buck vacuum.

- Famous Pneumatic parts

Features

- Automatic LED Controller(8 programs)(set :- Close,press,steam,Vacuum)

- Period of step:-.5/1.5/1.5/2.0/2.5 second

- 3 level safety production device.

- Output single on electric board (easy to check faulty).

- Stainless steel board, steam heating system.

- Top Buck steam sprays (italtmade value).

- Bottom buck vacuum.

- Famous Pneumatic parts

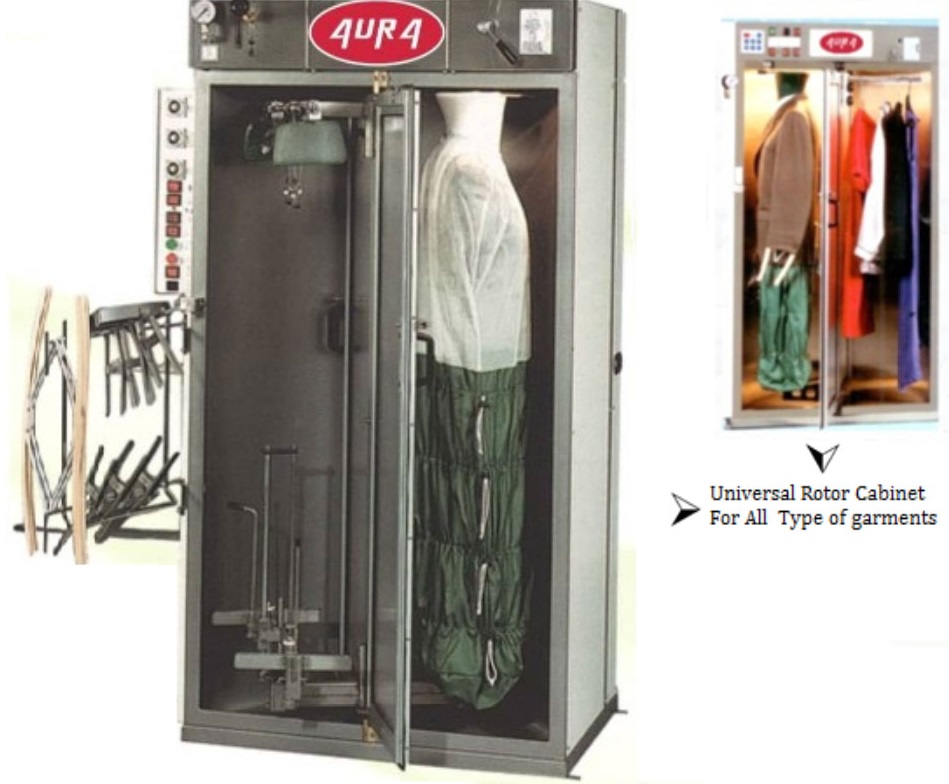

From Finisher Machine

- Aura Body formers can fully meet the most discerning requirement for finishing jackets, coats and dresses in the laundry dry-cleaning and garment industries.

- Both the machines are programmed by three timers: Steam, Hot air and Cold air. The Combination of three cycles makes the garment press perfectly.

- The machines are constructed from stainless steel (INOX AISI 304): Special powder coating on the body enable long rust free life.

- The AG 94 IB with inbuilt boiler is an energy saving garment former. The Steam condensate can return to the steam generator for lower steam consumption and does not require a steam trap.

- Available extras: Stream Iron assembly, Steam Gun, water spray gun, alternative dummies which are interchangeable with the standard utility dummy which is supplied with the basic unit.

| Model | AG-94 Premium | AG-94 Ultra-Premium |

|---|---|---|

| Air Working pressure | 6-8 Bar | 6-8 bar |

| Steam working pressure | 4-5 bar | 4-5 bar |

| Steam consumption | 15-20 kg/hr. | 15-20kg/hr. |

| Overall size (in mm) | 975x430x1400 | 1500x690x1600 |

| All inlet ¼” | ¼” | &ndnsp |

| Steam Inlet | ½” | ½” |

| Boiler drain | ½” | ½” |

| Pump motor | 2 kw | 2 kw |

| Return Outlet | ½” | 1/2” |

| Fan motor | 1.5 kw | 1.5 Kw |

| Voltage | 415v 3 ph | 415v 3 ph |

Universal Garments Finishing Machines

| Model | AG-92 Premium |

|---|---|

| Required Power | 400v/3+N/50Hz |

| Water Feeding | Hosepipe 13mm |

| Steam Inlet | 1/2 |

| Return outlet | 1/2 |

| Steam working Pressure | 4-5 bar |

| Steam Consumption | 16-20 kg/h |

| Boiler Drain | 1/2 |

| Boiler heating | 10/12/15/18 kw |

| Pump Motor | 0.6 kw |

| Fan Motor | 0.75 kw |

| Warm air outlet | 160mm |

| Encumbrance | 1060x1040x1820 |

| Net weight with boiler | 270 kg |

| Gross weight | 310kg |

| Overall Dimension | 1230x1000x2100mm |

Garment Packing Machine

Universal Packing Machine for all type of Garments

| Packing Machine |

|---|

| Best Class Garment Packing Machine |

| The Machine Comes with less maintenance and compact design |

| With longer function life |

| Ideal for every type of garment Packing |

| Specialized for every type of Indian and western wear |

| An efficient and convenient way for Laundry Outlet |

The ultimate solution in form finishing, the Pony cosmos revolving finishing cabinet is a flexible system that can be used as a double form finisher, pants toppet/Jacket finisher or mini tunnel. The Cosmos system provides a high-production, deskilled operation for retail stores & distribution centers, hotels, uniform rental services, apparel manufactures and dry cleaners.

Our Products

- Audaces Apparel Cad CAM

- Garment Cutting Printing Plotters

- Fabric Inspection Machine

- Conveyor Type Fusing Machines

- Flatbed Fusing machine

- Cutting Machines

- Auto Cleaning Machine- Spot Removing Machines

- Thread Sucking Machine

- Needle Detector Machine

- Industrial Laundry Machines

- Calendering Machine - Flatwork Ironer Pressing Machine- Drying pressing Machine

- Dry Cleaning Machine

- All in one Fully Automatic Industrial Laundry Machine

- Electric and Oil Fired Boilers

- Vacuum Ironing Tables - Industrial Pressing Table

- Laundry Pressing Machine - Hot Plates

- Turn Key Laundry Projects

- Shirt & Trousers Pressing Machines- Automatic

- Jacket Blazers Suits Coats Forming Finishing Pressing Machine

- Shirt Making Machines

- Shoe Washing Machines

- Industrial Carpet Washing Machines

- Sewing Machines

- Industrial Washing Chemical - Solvents

Our Clients