1. DIGIFLASH AND DIGITIZER FOR AURA APPAREL CAD/CAM TECHNOLOGY

It automatically detects the elements used by the industries and has simple and intuitive tools, as well as an exclusive assistant to scan large patterns. It does not require a special operator and can be operated by anyone. The AURA 360 integration with AURA equipment is in line with industry 4.0 concepts. It already provides data that allows analysis of efficiency, decision-making and production planning. The result is increased productivity, also in the production stage of the collection. The raw material has a significant weight in the cost of a part, and optimizing this feature is critical to achieve profitability on a large scale. Saving time can mean meeting delivery deadlines and increasing the speed of marketing of collections.

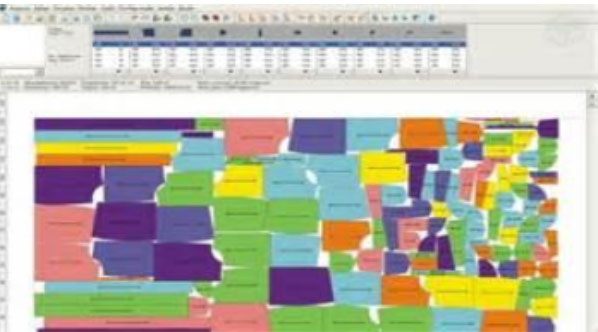

2. AURA APPAREL MARKER MAKING FOR AURA APPAREL CAD/CAM TECHNOLOGY

Features

- Grading on height.

- Allows for the creation and modification of notches with text.

- Inserts multiple notches (internal or outline), closes darts and adjusts grading.

- Transforms a pattern element in a symmetry line,determining the unfolding of the pattern when placed on the marker.

- Grades tangent, allowing the pattern (all sizes or selected sizes) to be graded on tangent or on line continuity.

- Offers control points, notches and auxiliary lines that can be moved with a click.

- Grades notches and internal lines.

3. AURA APPAREL MARKER EXPERT FOR AURA APPAREL CAD/CAM TECHNOLOGY

Features

- Allows for configuration of safety margin between patterns.

- Determines rotation, symmetry, and fold restrictions.

- Adjusts pieces for shrinkable fabrics.

- Displays all marker information, such as yield, width, length and number of placed pieces without having to open the file.

- Creates traces with precision and guarantees a high quality standard, from creation to end product.

- Automatically calculates the cutting matrix.

- Compatible with market’s main automatic cutting machines and with plotters of different makers and sizes.

4. AURA APPAREL MARKER MAKING EXPERT FOR AURA APPAREL CAD/CAM TECHNOLOGY

Features

- This product brings together all the functionalities of Audaces

- Configure the print speed and quality

- Save time, raw material and money, avoiding errors in marker making

- Allows the operator to manually place large patterns and then the small ones automatically, in the remaining spaces

- Creates traces with precision and guarantees a high quality standard, from creation to end product.

- Audaces Apparel Marker Queue.

- It is also possible to program a list of markers to be calculated at intervals when the computer is not busy.

- This is very useful during breaks or in the absence of the operator

- Computer keeps working on markers

5. AURA IDEA FOR AURA APPAREL CAD/CAM TECHNOLOGY

The new AURA Idea is fashion software totally innovative and integrates all stages of creation in the making, facilitates the production, simplifies the work, avoiding waste and has a unique business social network for the sharing of real-time models. Development, adoption and production are much more effective with AURA Idea

6. AURA CAD/CAM FOR AURA APPAREL CAD/CAM TECHNOLOGY

AURA 360 is an innovative concept of integrating the creation and production steps for you to achieve the success of your collection. A complete solution for you to generate more results, optimizing creative talent and resources through information and practicality. In fashion, whole company has a great challenge: to be assertive in design and profitable in production. AURA 360 is the ultimate platform you need for your business to meet and exceed this challenge.

7. MULTIPURPOSE PLOTTER CUTIING & PRINTING PLOTTER FOR AURA APPAREL CAD/CAM TECHNOLOGY

Plotters are available for wider width of 900, 1200 (mm) and also bigger sizes of 3000 & 4000 mm as well. Equipped for leather industry, high fashion industry. High Precision Cutting technology, compatible with any software. High printing speed of 60 m2/h which increases the speed of your production and also helps in cost efficiency. High printing speed of 120 m2/h which increases the speed of your production and also helps in cost efficiency. The high speed does not affect the cutting accuracy.

8. FLATBED CUTTING PLOTTER WITH AUTOMATIC PULLER FOR AURA APPAREL CAD/CAM TECHNOLOGY

Plotters are available for wider width of 900, 1200 (mm) and also bigger sizes of 3000 & 4000 mm as well. Equipped for leather industry, high fashion industry. High Precision Cutting technology, compatible with any software. High printing speed of 60 m2/h which increases the speed of your production and also helps in cost efficiency. High printing speed of 120 m2/h which increases the speed of your production and also helps in cost efficiency. The high speed does not affect the cutting accuracy.

9. AUTOMATIC SPREADING MACHINE FOR AURA APPAREL CAD/CAM TECHNOLOGY

Features

- The new curved design, paper perfect fit

- cut, perfect print results

- The ink associated with the frame design, more humane

- The independent dual-pressure structure of the paper to go round, more accurate

- Mark playing cut samples in one machine, you can print pictures, text, white paper, kraft paper cutting perfect print

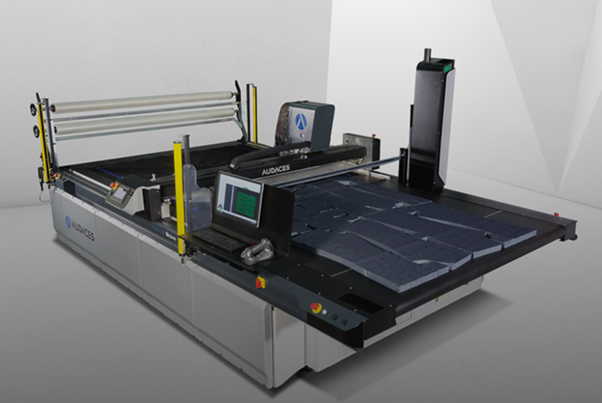

10. AUTOMATIC AURA NEOCUT MACHINE FOR AURA APPAREL CAD/CAM TECHNOLOGY

AURA Neocut Bravo is a machine for the Industry 4.0. With short deadlines, new product requirements and an increasingly competitive landscape, companies need to adapt and respond to change quickly. Holding information to create efficient planning is critical to getting the best results. With Neocut Bravo, the time, day, week and month of production are timed, aligned with your company goals and automatically provided for you to make decisions in complete safety. The continuous monitoring of the working conditions allows remote maintenance, remote diagnosis and the quick resolution of any situation. Manage better with the intelligence of Neocut Bravo integrated with the Neocut Mobile application to prevent losses and speed up your production. Keep up to date in real time to produce more.

Our Clients