Chennai

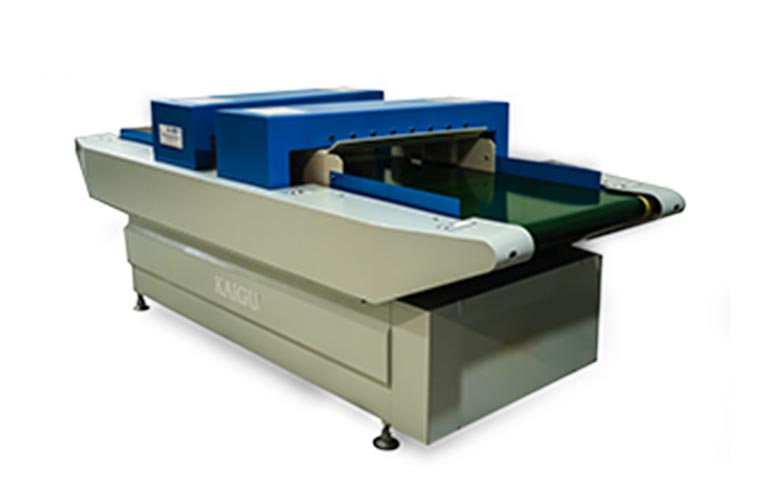

shirt fusing machine In Chennai

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Fusing Machine AG-1200/ AG-1600/AG-1800

Features- AG-1200

- Low temperature – high pressure technology for that enables fast glue line penetration for optimum bonding prevent any kind of distortion even on delicate fabrics.

- Energy efficient and low maintenance.

- Belt cleaner system attached.

- Pneumatic pressure control for precise pressure settings.

- Overheating automatic switch off.

- Auto Stop: Automatic Cooling system which cools the machine before completely stopping to prevent the belts from burning or getting damaged.

- Inspection table at loading area so that any fabric defect can be checked & stripes or check garment matching of the fabric & fusing is much convenient.

- Air cooling system at the receiving end of the machine which gives better peel strength to the fabric & interlining and prevents the finger marks or any other type of distortion of the fabrics.

- Individual on off system for lower heaters for fusing of sensitive fabrics where lower heating is not required.

- PID Digital Temperature Controller to set constant temperature for uniform and optimum bonding. Belt temperature, heating temperature & glue line temperature can be set as per your buyer’s requirement.

- Precise speed and pressure digital controls.

- Seamless Belt (also called endless belt or belt without joints). Much better strength than belts with joints.

- Double silicon roller.

- Individual PID temperature controls for upper and lower heaters that enables precise settings of upper and lower temperature. This is very useful for sensitive fabrics.

- Very effective for shirt fusing and fusing delicate fabrics: Max. Pressure on these machines is 9 kg/cm2 and is very effective for fusing of shirts where double fusing is required at one time. In other small machines, the fabric has to be passed twice for double fusing.

- Fully Automatic pneumatic belt control system that belt will not lean and run smoothly without any problems.

A Multipurpose machine which effectively performs the following operation:

- Fusing in all kinds of leather

- Laminating leather

- Leather foil Printing on all kind of leather

- Dual type which is applicable for fusing and curing purpose

- Manual handle is equipped for taking out fusing material during electricity failure

- Converted easily by switch from fusing to curing mode and vice versa

- Designed specifically for fusing

- Convenient to use with perfect fusing, as available a wide working range

- Automatic belt control with right and left

- Micro sensors at the end of the roller

- Roller-rewinding function optional

- Fully automatic belt deviation control

Features-AG-1600

- Low temperature – high pressure technology for that enables fast glue line penetration for optimum bonding prevent any kind of distortion even on delicate fabrics.

- Energy efficient and low maintenance.

- Belt cleaner system attached.

- Pneumatic pressure control for precise pressure settings.

- Overheating automatic switch off.

- Auto Stop: Automatic Cooling system which cools the machine before completely stopping to prevent the belts from burning or getting damaged.

- Inspection table at loading area so that any fabric defect can be checked & stripes or check garment matching of the fabric & fusing is much convenient.

- Air cooling system at the receiving end of the machine which gives better peel strength to the fabric & interlining and prevents the finger marks or any other type of distortion of the fabrics.

- Individual on off system for lower heaters for fusing of sensitive fabrics where lower heating is not required.

- PID Digital Temperature Controller to set constant temperature for uniform and optimum bonding. Belt temperature, heating temperature & glue line temperature can be set as per your buyer’s requirement.

- Precise speed and pressure digital controls.

- Seamless Belt (also called endless belt or belt without joints). Much better strength than belts with joints.

- Double silicon roller.

- Individual PID temperature controls for upper and lower heaters that enables precise settings of upper and lower temperature. This is very useful for sensitive fabrics.

- Very effective for shirt fusing and fusing delicate fabrics: Max. Pressure on these machines is 9 kg/cm2 and is very effective for fusing of shirts where double fusing is required at one time. In other small machines, the fabric has to be passed twice for double fusing.

- Fully Automatic pneumatic belt control system that belt will not lean and run smoothly without any problems.

Features-AG-1800

- Low temperature – high pressure technology for that enables fast glue line penetration for optimum bonding prevent any kind of distortion even on delicate fabrics.

- Energy efficient and low maintenance.

- Belt cleaner system attached.

- Pneumatic pressure control for precise pressure settings.

- Overheating automatic switch off.

- Auto Stop: Automatic Cooling system which cools the machine before completely stopping to prevent the belts from burning or getting damaged.

- Inspection table at loading area so that any fabric defect can be checked & stripes or check garment matching of the fabric & fusing is much convenient.

- Air cooling system at the receiving end of the machine which gives better peel strength to the fabric & interlining and prevents the finger marks or any other type of distortion of the fabrics.

- Individual on off system for lower heaters for fusing of sensitive fabrics where lower heating is not required.

- PID Digital Temperature Controller to set constant temperature for uniform and optimum bonding. Belt temperature, heating temperature & glue line temperature can be set as per your buyer’s requirement.

- Precise speed and pressure digital controls.

- Seamless Belt (also called endless belt or belt without joints). Much better strength than belts with joints.

- Double silicon roller.

- Individual PID temperature controls for upper and lower heaters that enables precise settings of upper and lower temperature. This is very useful for sensitive fabrics.

- Very effective for shirt fusing and fusing delicate fabrics: Max. Pressure on these machines is 9 kg/cm2 and is very effective for fusing of shirts where double fusing is required at one time. In other small machines, the fabric has to be passed twice for double fusing.

- Fully Automatic pneumatic belt control system that belt will not lean and run smoothly without any problems.

AG-1200

Swarovski/ Beads/ Embroidery/ Continuous Flowmatic Foiling Work transfer machine with special silicon springs in silicon rollers for additional cushion and high friction, as well as low-temperature transfer technology. For sensitive fabrics, a larger feeding area is available. For improved performance, use the cooling system. Turbo Heating System/ultra led for Low Power Consumption, Built for All Forms of High Fashion Garments

- Low temperature, high pressure technology allows for fast glue line penetration and optimal bonding, preventing any distortion, even on fragile fabrics. Completely automatic pneumatic belt control system guarantees that the belt does not lean and runs smoothly and without issues. Quite effective for fusing delicate fabrics and shirts: These machines have a maximum pressure of 8-9 kg/cm2 and are very good for fusing shirts when double fusing is expected at the same time. The cloth must be passed twice in other small devices for double fusing. Upper and lower heaters both have their own PID temperature sensors, allowing for accurate temperature regulation

- Double silicon roller

- Precise speed and pressure digital controls.

- Seamless Belt (also called endless belt or belt without joints). Much better strength than belts with joints.

- PID Digital Temperature Controller to set constant temperature for uniform and optimum bonding. belt temperature, heating temperature & glue line temperature can be set as per your buyer’s requirement.

- Individual on off system for lower heaters for fusing of sensitive fabrics where lower heating is not required.

- Air Cooling system at the receiving end of the machine which gives better peel strength to the fabric & interlining and prevents the finger marks or any other type of distortion of the fabrics.

- Inspection table at loading area so that any fabric defect can be checked & stripes or check garment matching of the fabric & fusing is much convenient.

- Auto Stop: Automatic Cooling System which cools the machine before completely stopping to prevent the belts from burning or getting damaged.

- Pneumatic Pressure Control for precise pressure settings Pneumatic Pressure Control for overheating automatic shut off.

- Attached Belt Cleaner System. Low-maintenance and energy-efficient.

Our Products

Handpicked Favourites just for you

Our Clients